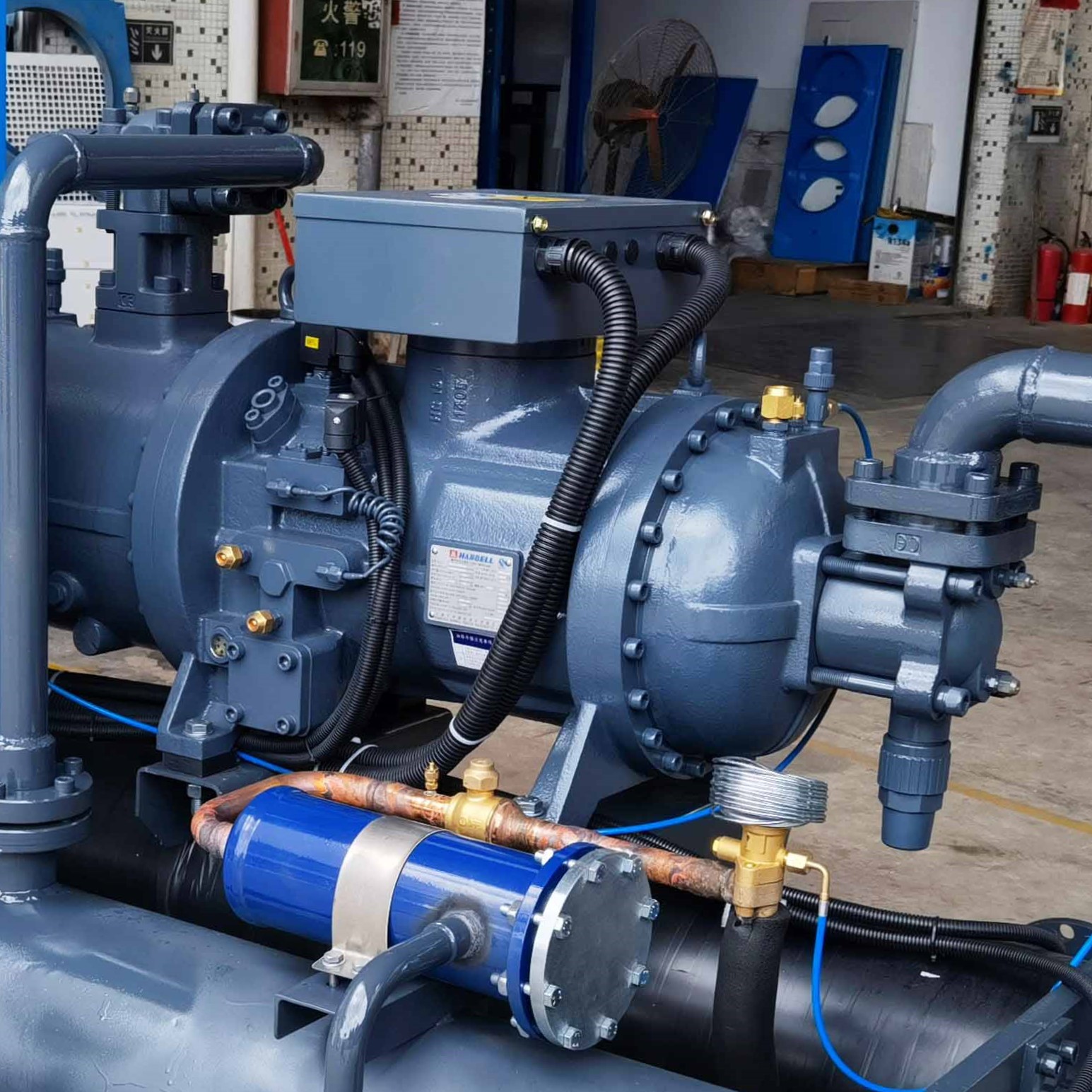

Water-cooled Screw Chiler

Industrial Water Cooled Screw Chiller are so named because they use screw compressors. Their cooling capacity is larger than that of scroll Water Cooled Chillers and they are mainly applied in chemical plants, ink printing factories, automobile manufacturing plants, central air conditioning systems or other large-scale industrial refrigeration fields.

Water Cooled Screw Chiller units are water chiller units with various forms of screw compressors as the main unit. They are assembled refrigeration devices composed of screw refrigeration compressors, condensers, evaporators, thermal expansion valves, oil separators, and automatic control components and instruments. Currently, screw water chiller units are increasingly widely used in the field of refrigeration and air conditioning in China, with a typical cooling capacity range of 700 to 1000 KW.

Water Cooled Screw Chiller units have a compact structure, stable operation, stepless cooling capacity adjustment, good energy efficiency, and few vulnerable parts. Industrial Chiller suitable for large and medium-sized air conditioning refrigeration systems in high-rise buildings, hotels, restaurants, hospitals, research institutes, etc., with a cooling capacity of 580 to 1163 KW.

How it works:

The principle of screw chiller: The screw chiller is named so because its key component, the compressor, adopts a screw type. The unit starts with the gas refrigerant coming out of the evaporator. After being adiabatically compressed by the compressor, it becomes in a high-temperature and high-pressure state. The compressed gas refrigerant is then cooled and condensed under constant pressure in the condenser. After condensation, it turns into a liquid refrigerant, which then expands through a throttling valve to a low pressure, becoming a gas-liquid mixture. Among this, the liquid refrigerant at low temperature and low pressure absorbs the heat of the substance to be cooled in the evaporator and reverts to a gaseous state. The gaseous refrigerant then re-enters the compressor through the pipeline to start a new cycle. These are the four processes of the refrigeration cycle and also the main working principle of the screw chiller.

Application Range:

The Industrial Water Cooled Screw Chiller is widely used in industries such as plastics, electronics manufacturing, electroplating, pharmaceuticals, chemical plants, automobiles, central air conditioning systems, ultrasonic cooling, printing, and other industrial production and manufacturing plants. This chiller can precisely control the temperature required for modern industrial manufacturing, significantly improving both efficiency and product quality.

Product parameters:

|

|

Single Compreessor Series

|

| Parameters /Type |

40WSS |

50WSS |

60WSS |

70WSS |

90WSS |

100WSS |

| Rated Cooling Capacity |

50HZ |

Btu/h |

513807 |

653440 |

|

819701

|

947385 |

11648571 |

| Kcal/h |

129407 |

164574 |

|

206449

|

|

293379

|

| KW |

150.5 |

|

207

|

240.1 |

277.5 |

341.2 |

| USRT |

42.8 |

54.4 |

58.9 |

68.3 |

78.9 |

97 |

| Input Power Supply |

|

|

~380V/3PHASE/HZ |

| Input Power |

|

KW |

29.9 |

37.2 |

39.9 |

46.3 |

53 |

64 |

| Input Power Supply |

|

|

R22/407C/134A |

| Compre ssor |

Pattern |

|

Semi-hermetic Screw Expan sion Value |

|

|

%

|

100-75-50-25 |

| condensr |

|

|

High effective inner Grooved Copper shell and pole |

| Evaporator |

|

|

Tube-in-shell Heat Exxhanger |

| Temperature Controller |

|

|

Effictive Inner grooved COpper Shell Heat Exxhanger |

| Safety Device |

|

|

High/low pressure opening, exhaust overheat protection, hot melt plug,anti-freeze thermostat,etc. |

| Machine Weight |

|

Kg |

750 |

850 |

900 |

1100 |

1280 |

1600 |

Reviews

There are no reviews yet.