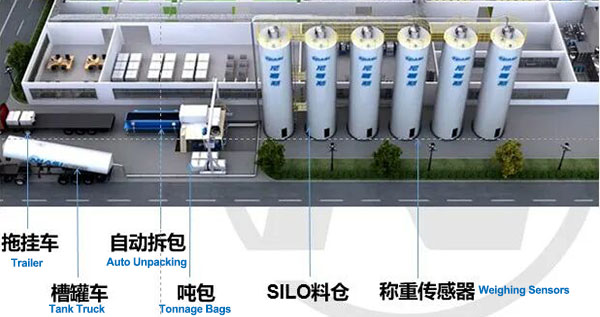

In the plastics industry, the traditional feeding process involves manual palletizing, forklift transportation, warehousing, forklift transportation, mixing room, unpacking/weighing/mixing, and finally feeding. This traditional feeding process carries high safety risks, a high risk of raw material breakage, inaccurate formulations, low production efficiency, and high management costs.

How can we overcome the shortcomings of traditional feeding? How can we improve production efficiency and product quality? Dongguan Niasi, a renowned company specializing in efficient warehousing and intelligent feeding systems for many years, has tailored a comprehensive suite of solutions for downstream customers. This system addresses the entire process of raw material transportation, storage, conveying, Dehumidification and drying, and metering, providing comprehensive automation upgrades and efficiency optimization for user factories.

Niasi’s next-generation IoT-enabled intelligent feeding system is primarily used in the plastics products industry, encompassing intelligent raw material handling and feeding for various processes, including injection molding, blow molding, bottle blowing, extrusion, film blowing, and cast film.

The intelligent upgrade of China’s manufacturing industry is an inevitable trend, and the flexible packaging industry is no exception. Only by adapting to the call of the times can we seize the initiative. Nigas’ professional, efficient, intelligent, and flexible customized system solutions will surely help more flexible packaging companies reduce costs, increase efficiency, and enhance their core competitiveness.