The manufacturing industry is gradually transforming towards intelligence and intensification. Traditional material feeding modes suffer from pain points such as low efficiency, high costs and heavy reliance on manual labor, which have become a stumbling block to enterprise development. With 18 years of deep cultivation in intelligent central material feeding systems, Niasi leverages its accumulated industry experience and continuous innovation of its technical team to launch a one-stop solution for central material feeding systems, integrating full-process services including system scheme design, equipment construction, intelligent control, and safety & environmental protection.

For 18 years, Niasi has focused on the R&D and services of material feeding systems for industrial manufacturing, serving more than 500 customers and establishing an excellent reputation in the industry. The one-stop solution for central material feeding systems is tailor-made by Niasi for the production needs of different industries based on years of industry practice, covering the full life-cycle services from system planning to implementation and operation maintenance.

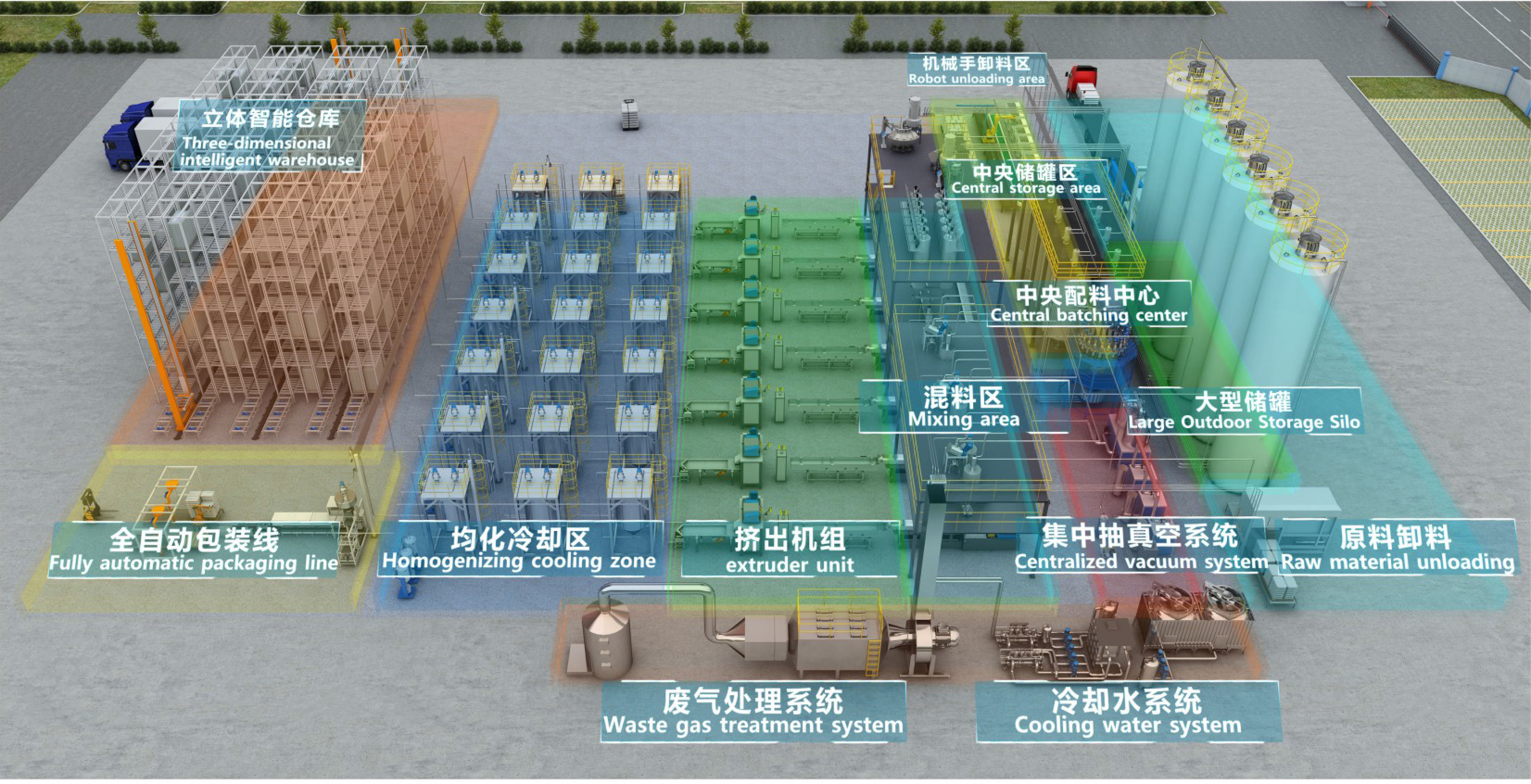

Design and Construction of Central Material Feeding System

The central material feeding system consists of multiple pieces of equipment and components, including storage silos, pipelines, conveying equipment, control equipment and monitoring equipment, which requires overall design and construction.

Determination of Raw Material Types and Storage Methods

According to production needs, determine the types and storage methods of raw materials (including granules, powders, liquids, etc.), as well as adopt positive or negative pressure conveying methods.

Connection of Storage Silos and Production Equipment

The central material feeding system needs to connect storage silos with production equipment, and select appropriate pipelines and connection methods based on actual needs.

Configuration of Automatic Control System

The central material feeding system shall be equipped with an automatic control system including sensors, controllers and actuators, which can real-time monitor and control parameters such as raw material supply volume, pressure and flow rate.

Realization of Multi-point Feeding and Flexible Configuration

The central material feeding system can meet the raw material supply needs of multiple production equipment. Through flexible pipeline configuration, different types of raw materials can be conveyed to the corresponding equipment respectively.

Optimization of Production Efficiency

Through automated and intelligent control, the central material feeding system can reduce manual intervention and operation time, and improve production efficiency. Meanwhile, real-time monitoring and control of raw material supply volume can avoid excessive or insufficient feeding, further optimizing production efficiency and product quality.

Ensuring Safety and Environmental Protection

The central material feeding system needs to pay attention to safety and environmental protection issues, including preventing raw material leakage, ensuring operational safety, and reducing noise and pollution, with corresponding measures and standards adopted.